|

Even small leaks in the wrong places cause downtime, disruption, and costly damage. The aftermath usually ties up resources with clean-up and repairs to the damaged area. Why suffer these costs when reliable, distributed leak detection is available? TraceTek technology lets you detect leaks at their source, even pinpoint their location, so you can stop damage before it starts. Thousands of facilities throughout the world rely on TraceTek leak detection systems to protect data and telecommunication centers, commercial buildings of all kinds, libraries and archives, and museums.

The TraceTek Leak Detection and Locating System was developed by the international material science manufacturing company Raychem in the early 1980's and Raychem products are in use in tens of thousands of leak detection appliactions worldwide. The TraceTek products group became part of Tyco Thermal Controls when Raychem Corporation was acquired by Tyco International in 1999.

TraceTek leak detection systems are the most reliable and adaptable fluid leak detection systems available. The TraceTek system design is a simple and sure detection circuit that can also locate. The system continuously performs integrity checks with its four-wire construction. A liquid creates a circuit between the sensing wires to trigger an alarm. The system has no moving parts and does not require calibrations. The locating system pinpoints where liquid contacts the sensing cables with 0.1% precision. The locating module measures the current and the voltage drop in the second sensing loop and simply applies Ohm's law (R=V/I). The microprocessor-based alarm and locating module (TTDM-128) continues to monitor after a leak and realarms if any major change occurs. It also keeps a log of events and has a built-in system-wide diagnostic function. In addition to alarm relays, its interfaces include a 4-20 mA current transmitter and an RS-232/RS-485 communications port.

Most building fires are the result of wet wires or failed insulation. High temperature electrical arcing is a likely result of water released in the presence of higher voltage and current requirements to operate most machinery.

TraceTek Fluid Leak Detection Leak Sensing Cables Pentair Thermal - Fluid Leak Detection

Fluid Leak Detection System for Commercial Buildings Leak Detection for Hydrant and Airport Applications TraceTek Fuel Leak Detection Systems for Tank Farms

Factory Mutual issued a new approval report FM-7745 for diesel back-up generator systems. View the FM Approval Guide 7745

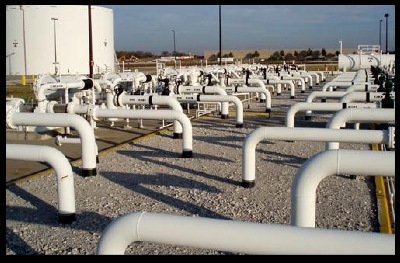

At terminals, refineries, wharfs, and oil fields, cable is strapped to the bottom of an above-ground or racked piping system. TraceTek sensor cable provides the same high sensitivity and accurate leak location as its below ground counterparts. The sensor cable is designed and installed to detect the first drips of fuel or oil.

Cable is installed around the circumference or beneath tank floor plates above ground storage tanks as a permanent safeguard against undetected leakage through corroded bottom plates.

TraceTek cable provides round-the-clock, leak detection, and precise location. Cable is installed and services through access risers in the apron. Other airport leak detection systems are based on periodic pressure decay measurements and a given section of pipe may be tested only once every 30 days. TraceTek systems provide early detection and provide precise information on where to dig.

For batch lines and transfer lines where SCADA is ineffective or has prohibitive initials costs, TraceTek systems typically provide a low cost option, better sensitivity, and actionable alarms.

Operators of Hazardous Fluid Pipelines traversing "High Consequence Areas" should consider additonal measures to detect and mitigate pipeline leaks. In the USA, API 1160 list Hydrocarbon Sensing Cables as mitigating devices.

TraceTek cable monitors water-heated or cooled ventilation equipment. If a leak is detected, the system automatically shuts off a supply valve - to prevent costly damage to office equipment.

TraceTek systems provide 24-hour leak detection on unmonitored basement and equipment floors. TraceTek fuel-sensing cable is available for back-up diesel generators and other fueling applications.

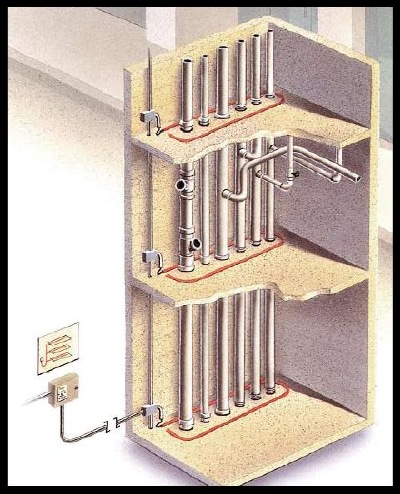

Leaks in vertical service columns often propagate to several floors. TraceTek systems offer layout flexibility to handle widely distributed areas with branches or zones. Sensing cable on each floor provides early and quick detection - and the alarm and locating module pinpoints the location.

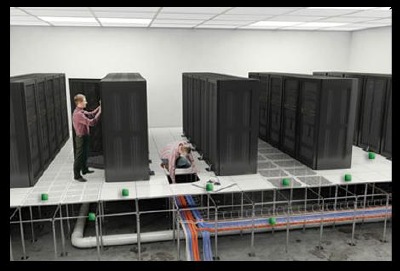

Network servers and routers are sometimes housed in rooms not specifically designed for their protection. TraceTek cable can be installed to monitor hazards wherever they occur. for example, cable is placed at the perimeter of sub floors and in trays below overhead piping.

In a raised-floor computer room, the TraceTek system provides distributed coverage that finds a leak before it becomes a problem. Cable is laid out at the perimeter of a room, near drains, water piping, and air conditioning.

TraceTek sensing cable is installed in a tray below the sprinkler system piping. By directly monitoring the sprinkler system and water supply piping, leaks are detected early before they can do a lot of damage.

TraceTek cable provides constant monitoring of unmanned locations such as basements storage areas, where overhead water pipes and seepage or flooding present risks. Early warning can help prevent disasters.

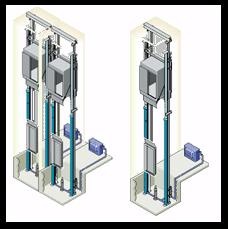

It is never a good idea to allow corrosive chemicals or hydrocarbons to leak from their containment vessel. This is particularly true in a commercial building or institutional facility where customers, guests, patients, and other individuals not familiar with these materials have the potential to come into contact with them. This is a safety issue first and a liability issue second. However, elevator pits represent an additional and different type of safety threat. Should hydraulic oil leak into an elevator pit from an elevator hydraulic system and then the building become involved in a fire, the hydraulic oil could have an impact on the speed with which the fire can be controlled. If equipment located in an elevator pit develops a hydraulic oil leak, a layer of hydraulic oil will build on the pit floor. When firemen then put water on a fire, the water finds its way to the bottom of the pit and the oil floats on top. When the pit is full, additional water making its way into the pit pushes the oil out at the top. When the oil leaves the confinement of the pit, it begins to spread. At this point, adding more water only spreads a high-grade fuel into the fire. Water is no longer a suitable tool for fighting the fire.

Whether your concern is gasoline, jet fuel, diesel, or bio-fuels, TraceTek can provide a customizable leak detection system tailored to meet your needs. With the TraceTek leak detection system, you can detect and pinpoint the source of a leak to help you take decisive action long before the spill can ruin your reputation.Safety is the number one concern of most companies involved in the handling of petroleum fuels and protecting the environment is a close second. The regulatory framework in both areas is getting progressively tighter, so if your business involves the production, transporation, storage, refining or consumption of fuels, you need to consider the possibility of a leak.In some situations a potential leak can be anticipated. A valve pit, an overfill containment or a low point sump is an ideal location for a fast acting fuel probe. Quickly knowing that fuel is accumulating in an unexpected area can be the key to avoiding a catastrophic accident or expensive clean-up. Our fast fuel sensor provides an immediate signal of the prescence of hydrocarbons so that you can deal with the issue - fast! Don't make the mistake of thinking that a "slow" leak is a "small" leak. A slow leak results in a large spill if the detection system is too insensitive to detect leaks below a given threshold or below a certain percentage of flow. Far too many leaks are discovered when someone notices the smell of fuel or after surface/below-ground water has become contaminated. Hydrocarbon sensing cables lay around or under potential leak sources; it tells you if there is a problem and where it is. All TraceTek systems for hydrocarbon leak detection are suitable for installation in hazardous locations with appropriate selection of zener safety barriers and power supplies.

| |